From headlights to mufflers, chassis to interiors and everything in between, Intertek offers the professional automotive testing and certification services manufacturers and OEMs need to set their products apart

Automotive products today need to be safe and strong. Is your chassis built to defend against salt spray erosion? How does your engine respond at high altitudes? Will your vehicle or component withstand years of vibration?

Intertek can help substantiate the durability of the engine or shocks, for example, or collaborate on a build of specific test methods for key areas of product development. Expedite environmental exposure testing for everything from -45°C to 177°C, optimize thermal shock or tensile strength testing, targeted electrical testing, and much more. Automotive testing supports materials testing, performance testing, research and development, safety, and certification for both established and developmental alternative energy fuels and new technologies.

But Intertek offers much more than automotive testing and certification; we are a Total Quality Assurance provider. Through our global network of state-of-the-art automotive testing labs and industry-leading technical expertise we provide innovative and bespoke Assurance, Testing, Inspection and Certification services throughout the operations and distribution chains delivered consistently with precision, pace and passion, enabling our customers to power ahead safely.

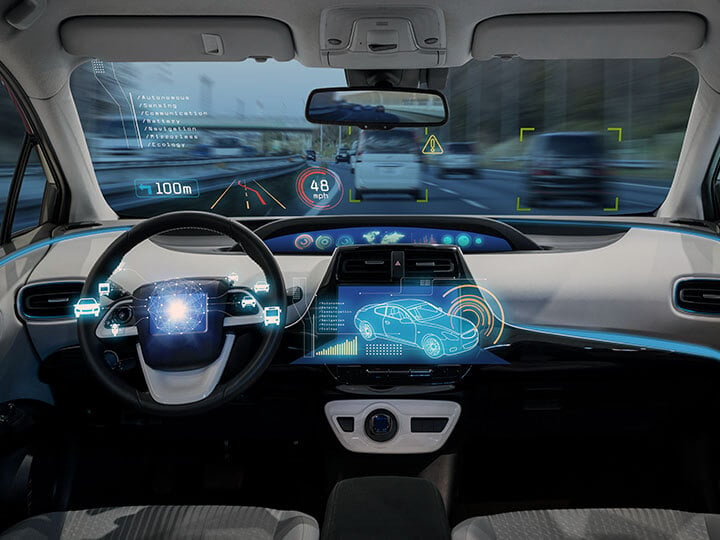

Autonomous & Connected Vehicles

Intertek drives the future of transportation by offering trusted evaluation services for autonomous and connected vehicles. With expertise in ADAS, V2X, and automotive cybersecurity, Intertek ensures safe development, compliance, and performance. Supporting OEMs and innovators, Intertek advances smart mobility and IoV, delivering confidence in next-gen automotive technologies through decades of experience in safety, testing, and connected ecosystems.

Automotive Testing Solutions

Intertek delivers comprehensive automotive testing services, supporting product development, performance optimization, and regulatory compliance. With ISO 17025-accredited labs and decades of expertise, they provide reliable data, enabling manufacturers to meet global standards. Specializing in propulsion, electronics, and safety systems, Intertek helps OEMs and suppliers enhance reliability, reduce risk, and accelerate development with tailored testing solutions.

Electric and Hybrid Vehicles

The EV and HEV market is rapidly growing, driven by electrification technologies and global adoption. Intertek supports this shift with bespoke testing services for cars, motorsport, suppliers, and aerospace. Its award-winning Global EV Testing Centre and Milton Keynes facility provide advanced solutions to ensure performance, safety, and customer satisfaction, meeting the industry's evolving demands.

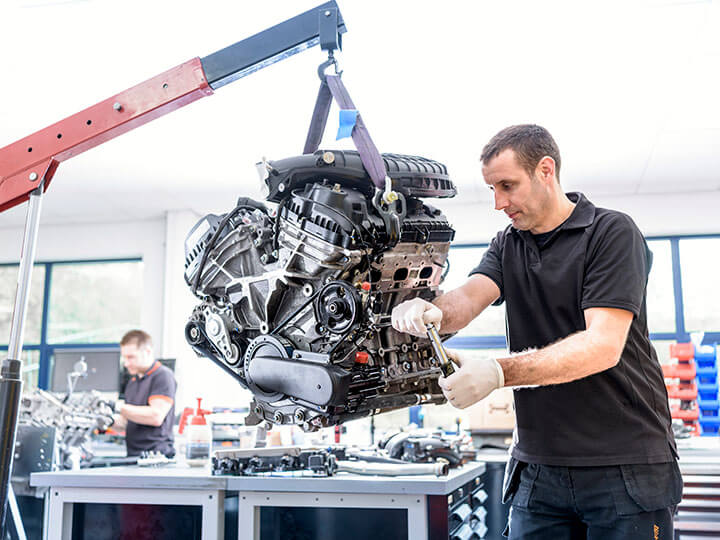

Engine and Gears

Intertek offers comprehensive testing and evaluation for automotive engines, gear systems, and powertrains. With advanced labs in North America and the UK, they support combustion and hybrid engines, ensuring emissions compliance, durability, and efficiency. Partnering with OEMs and suppliers, Intertek accelerates design, validates technologies, and enhances innovation for sustainable, high-performance powertrain solutions worldwide.

Fuel and Lubricants Testing

Intertek's Automotive Research Laboratories offer advanced testing for fuels and lubricants. Specializing in lubricant testing, engine durability, and SHED evaluations, we leverage cutting-edge facilities and global expertise to streamline regulations. Our services help you stay ahead of evolving technologies and ensure your products reach customers faster than any competitor.

Materials, Systems and Components

Automotive materials, systems, and components are vital to vehicle design, combining metals, polymers, and composites for strength, durability, and lightweight efficiency. Integrated systems like powertrains and safety features enhance functionality, while components like gears and lighting ensure performance. Modern designs prioritize sustainability, cost-effectiveness, and fuel efficiency, shaping vehicles' safety, aesthetics, and reliability.

Our Automotive Labs

Intertek testing laboratories support the automotive and transportation industries worldwide by assisting clients in developing, enhancing, and maintaining high-quality products, components, and systems. With strategically located facilities across the globe, Intertek provides comprehensive testing services, ranging from materials to fully assembled components, ensuring compliance with standards set by OEMs, governments, and industry regulations.

Automotive Standards

Automotive testing standards are crucial for ensuring safety, reliability, performance, and regulatory compliance. They establish uniform benchmarks for evaluating materials, components, and systems under various conditions, helping identify potential failures before production. With testing expertise across a wide range of automotive products, systems, and technologies, Intertek tests to both national and international standards helping facilitate global market access.