Food and Packaging

08 May 2020

How Hot is Too Hot?

The food and beverage industries are constantly evolving and adopting innovative solutions for consumers along the way. At the forefront of food and beverage packaging are items such as microwaveable on-the-go meals, self-heating coffee & ready-to-eat meals, or packaging utilizing induction technology to heat foods wherever we are; we even have smart travel mugs that can be charged via USB.

As we continue to push the boundaries of food and beverage packaging with items that facilitate easy meal solutions, and as we provide more convenience and variety to consumers than ever before, it is important to understand the potential safety issues associated with product innovation. Let us focus on burns and the measures required to stop them from occurring.

As we continue to push the boundaries of food and beverage packaging with items that facilitate easy meal solutions, and as we provide more convenience and variety to consumers than ever before, it is important to understand the potential safety issues associated with product innovation. Let us focus on burns and the measures required to stop them from occurring.

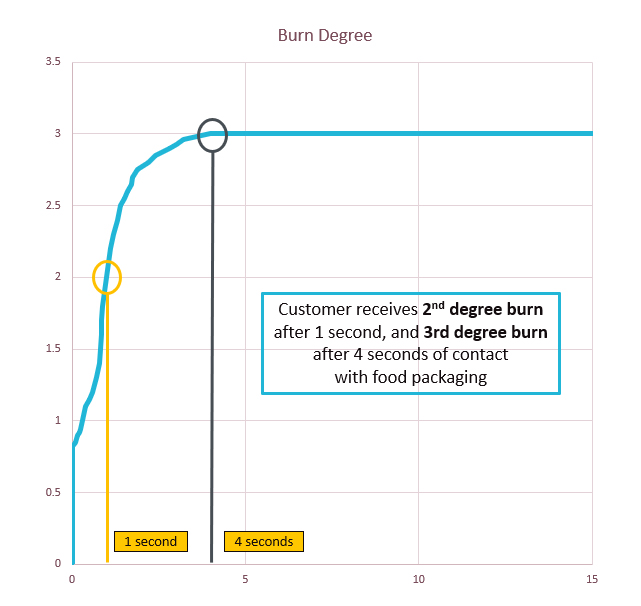

Understanding how quickly burns can happen and the critical factors that affect the temperature of the skin is vital to designing safer products for consumers. Burn severity is a factor of temperature and exposure over time. The graph illustrates a potential scenario in which a consumer has microwaved a product and has acquired a burn. As shown on the graph, within 2 seconds of removing the item from the microwave, the skin on the consumer's hand is exposed to enough heat to cause a 2nd degree burn. After 4 seconds, the consumer's hand is exposed to enough heat to cause a 3rd degree burn. A serious burn requiring medical treatment or hospitalization may occur if a consumer is unaware of how hot a product can get and does not react in sufficient time.

The good news is that food companies can combat potential burns with an improved understanding of the crucial roles that food items, packaging materials, cooking instructions, consumer behaviors, and reaction time have in a potential burn scenario. For a burn to occur, we need to understand how hot our skin gets, not just how hot the actual food or packaging is. Imagine a turkey that is covered in foil and is roasting in the oven for 3 hours at 350°F (176°C). When we take the turkey out of the oven, we can remove the foil and hardly feel the heat. The heat transferred from the foil is minimal and is quickly absorbed by the skin. However, if we put our hand inside the turkey, the heat will rapidly increase the temperature of our skin and can cause a severe burn.

So what does this mean for food designers and brand owners? It means there are many factors that affect temperature to consider! For example, switching from foam to cardboard packaging for a particular soup, or switching from chicken noodle soup to tomato soup but keeping the same container may result in a different amount of energy being transferred to the consumer's skin. For self-heating food and beverages that use an exothermic chemical reaction that is initiated by exposure to air, the amount of air exposure is critical a slight increase may be the difference between a safe and unsafe level of heat.

Gathering temperature data and, in particular, the potential burn degree over time to a consumer's skin, has helped many of our customers to design safe products without compromising innovation. To learn more about how Intertek Product Assurance can help, visit us at: https://www.intertek.com/product-assurance/safety/.

Don't miss the opportunity to learn from the experts...

Intertek will be offering a complimentary Webinar, "Food and Packaging: How Hot is Too Hot?" on May 28, 2020 at 10am EDT, 2pm GMT, and 4pm CEST. Register here.

Eleanore Pittman,

Senior Safety Manager, Product Assurance

Health, Environmental & Regulatory Services (HERS)

Today's expert blogger is Eleanore Pittman. Eleanore is a Senior Safety Manager for Intertek Product Assurance and has been at Intertek for 8 years. Where standards fall short, Ellie serves to educate clients on potential product hazards and develop customized safety assessments to meet their unique needs. With her thorough knowledge of product safety, Ellie is able to consult with clients on potential product hazards and advise them on mitigation strategies that can increase their brand value by drastically reducing a product's potential to injure a consumer or result in a product recall. Ellie attended the University of Illinois at Urbana-Champaign where she received a B.S. in Chemistry and has also obtained an MBA from Western Governors University.