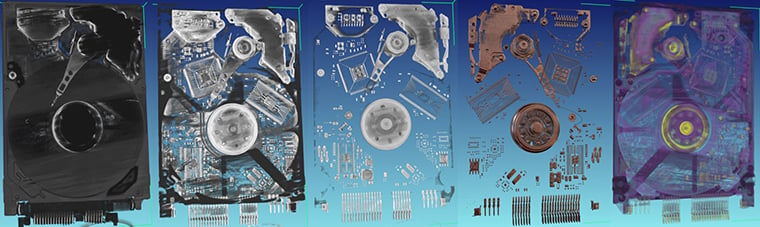

This advanced X-Ray technique produces 3D images to identify internal component features and potential defects

New designs and technology are increasingly incorporating complex components and many of these are now made using additive manufacturing techniques, which can reduce cost, weight, size and increase performance. X-ray Computerised Tomography (XCT or CT) is a particularly useful technique to inspect these type of components as it can provide clear internal images which would not be possible using conventional X-Ray or other non-destructive techniques.

The envelope for our XCT machine is 810 mm x 1210 mm.

CT scanning combines multiple X-Ray images taken from different angles as the component or object is slowly rotated between the X-Ray source and the detector plate. Specialized software combines these images to create a 3-Dimensional image that can then be viewed by slicing it to identify internal features and potential defects. The technique can also be used to provide accurate measurements between features in all 3 axes.

CT provides greater resolution than conventional X-ray and has the capability to identify the location of features or discontinuities in 3D. The associated software creates a 3D model of the component that can be analysed slice by slice. The models are similar to a CAD model and can be compared with the original model.

Additive manufacture components are often complex shapes and can be prone to delamination between layers. CT scanning is therefore particularly well suited to the inspection of these components. The power of the X-Ray source can be varied. Higher powers penetrate denser materials whilst lower powers deliver higher resolution.

CT is a useful non-destructive tool for failure investigations and research and development as it provides the capability to investigate features that would be not accessible to conventional X-ray or other non-destructive methods.

The following lists our approvals and accreditations for XCT:

- Rolls-Royce Approval (Aerospace & Nuclear)

- Airbus Approval

- Safran Approval

Computerised Tomography Fact Sheet

Non-Destructive Testing Laboratory & On-Site Services Brochure

Carbon Fibre Composites Fact Sheet