Owners and operators of complex equipment and facilities need tools to manage the life of their assets. Intertek’s innovative and technologically advanced solutions help companies maintain equipment reliability and safety, determine equipment remaining useful life estimations, and manage inspection data.

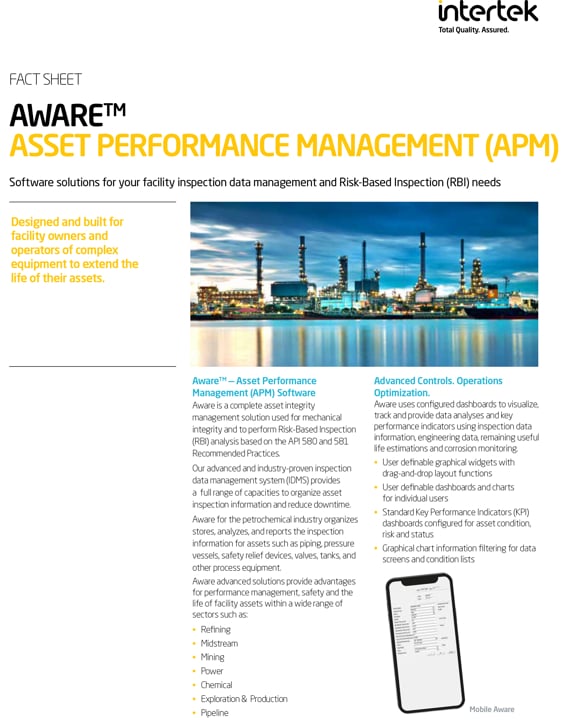

Aware APM software for the oil, gas and petrochemical industries is used to organize the inspection information of assets such as piping, pressure vessels, safety relief devices, valves, tanks, and other process equipment. It is the only APM software that utilizes a web-based environment in which users can quickly navigate and visually locate asset information.

Our inspection data management system has a proven track record of over 15 years of Total Quality Assurance service and is used at almost 300 facilities worldwide.

Aware helps users improve the reliability and safety of equipment by organizing every aspect of inspection activity. It includes forms, reports, and views necessary to meet the safety and regulatory requirements of API codes and OSHA regulations. It turns complex data into accessible information, helping inspectors, engineers and owners/operators make faster and more accurate run, repair or replace decisions which can reduce the risk of forced shutdowns. Users can configure dashboards to visualize, track and analyse data that acts as key performance indicators on information such as inspection data, engineering data, remaining useful life and corrosion monitoring data, which are all key elements of a good inspection data management tool . As Aware provides easy access to information through its web-based interface, users can quickly navigate and visually locate asset information.

Industries Served:

• Refining

• Midstream

• Chemical

• Exploration and Production

• Pipeline

• Petrochemical

Key Features of our Inspection Data Management System:

Corrosion monitoring

Stores and tracks corrosion monitoring locations (CML), inspection dates, and retirement dates on any type of equipment or component. Automatically calculates minimum allowable wall thickness (TMin) and corrosion rates.

Engineering Data

Complete engineering, process and manufacture’s data is stored and easily accessed within the program.

Activity Scheduling

Any type of activity can be scheduled and monitored by the user such as visual inspection, repairs & failures.

Data Transfer

Data can be imported/exported through automated load sheets, excel, SAP®/ MAXIMO® links and industrial data loggers.

Dashboards

Users can create custom dashboards to view important data and key performance indicators (KPIs).

Drawing Interface

Aware data can be over laid on existing CAD Drawings and can then be viewed through the Aware viewer.

Document Management

Any type of file can be attached in multiple locations within the program. Excel, word, pictures, movies, pdf to name a few.