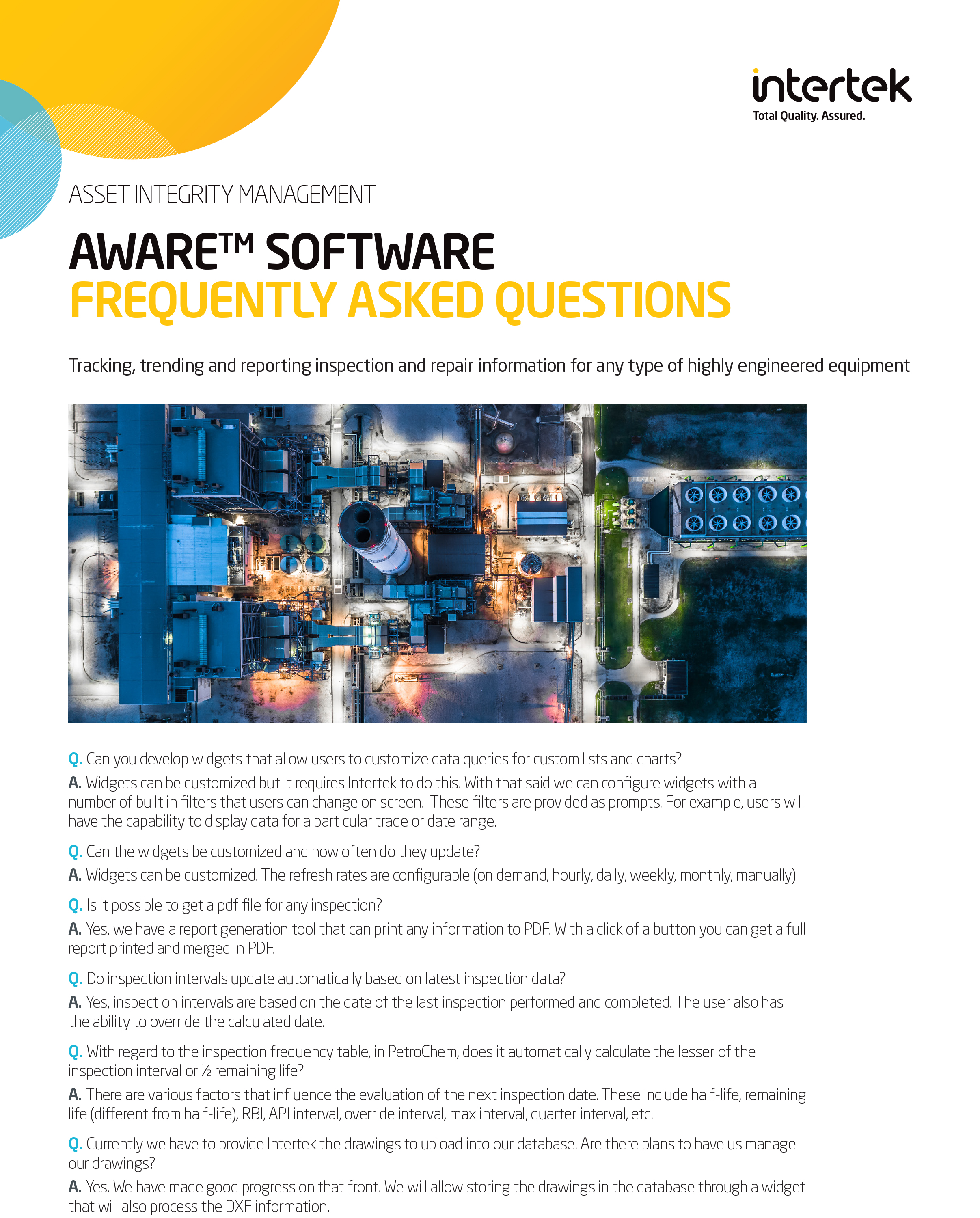

Heat Recovery Steam Generators (HRSGs) and their associated combined cycle plants are now needed to run base load operations to meet electric demand and our integrity management software tracks, shows trends, reports and collaborates on inspections, failures and repairs.

Keeping heat recovery steam generators operating at peak capacity and efficiency requires a program that includes inspections and tube failure avoidance. The Aware HRSG integrity management software is used to track, trend, report, and collaborate on HRSG inspections, failures and repairs. Our steam generator integrity management software provides much-needed solutions to the owners and operators of conventional boilers and HRSG’s to help them increase their reliability, and decrease the amount of time and money spent on forced outages and unexpected “surprises” during routine outages. HRSG owners can meet their reliability, efficiency and productivity goals by using our Total Quality Assurance Aware HRSG integrity software for critical tasks such as:

- Preventing Tube Failures

- Planning for Outages

- Quick Recovery from an outage

- Sharing Knowledge

Preventing Tube Failures

Finding the root cause for a failure is a very important step in preventing future failures. However, it is not beneficial to know the root cause if you have no method with which to apply that knowledge to prevent future failures. Aware HRSG integrity management software lets you easily document the root cause and analyze it. The customized Aware queries and portals give you powerful tools to break down the failures by component, root cause and other significant parameters. Similar units can be compared across a fleet of HRSG’s in order to locate trends and make the necessary adjustment to preventive maintenance protocols.

A key indicator of where and when future leaks are going to occur is in the historical data of tube leaks at an individual unit or across a fleet of similar units. Visual Aware integrity software provides the tools necessary to record, view and report tube failures and display them on plant specific interactive AutoCAD drawings. Analysts immediately see tube failures for a specified date range displayed on a drawing with color-coded criteria settings for failure cause, description, repair type, repair status, unit, etc. This visual analysis tool, along with the powerful reporting and trending functions, allows engineers to have better insight into the condition of the boiler and how it is aging.

Repairs can be easily documented and visualized using Visual Aware integrity software. At times it may be necessary to perform a temporary repair in order to get the unit back on line promptly. It is imperative that temporary repairs, material changes, and repairs requiring future “check-ups” are documented in a system in which they can be easily located and planned for during preparation of the next scheduled outage. Aware has excellent search capabilities that help you track those items and make sure they are included in your upcoming outage work scope.

NDE inspections and condition assessments can be documented and retrieved in Aware heat recovery steam generator integrity management software.

UTT and other NDE technology are often used to measure/predict where problems will occur, so the Aware HRSG module has been designed to manage this data as well. Users can take readings, upload them into the system and perform calculations over a specified window in time. Measurements, wastage rates, remaining life, etc. can be displayed on the drawings, and color-coded symbols are automatically applied to highlight potential trouble spots.

By reviewing past failures, inspections and Non-destructive Testing (NDT) measurements, analysts can better predict which trouble spots are likely to lead to forced outages. This enables better decision making regarding how to spend limited maintenance dollars, thus guaranteeing that the greatest bang for the buck is achieved. The Aware HRSG integrity management software impacts “the bottom line” by enabling engineers to make the right decisions to reduce the frequency of forced outages.

Planning for Outages

The Aware HRSG software allows engineers and planners to determine where to focus attention during planned outages, and also provides quick access to the data necessary to get back online quickly after forced outages induced by tube failures. When failures are documented in the system, often a recommendation is made to re-inspect or make a more permanent repair during the next planned outage. These recommendations automatically appear in the Outage Planning screen to prompt planners to create the necessary work orders for the appropriate outage.

Problems can sometimes be attributed to the design of the HRSG. Such problems will most likely show up on other similar units. In some cases, the problems may be due to operating conditions and chances are that units with similar operating conditions will have the same problem. Aware provides a ‘Liability Matrix’, where liabilities or issues on one unit can be propagated to other similar units. This helps the planners in knowing what to look for and enriching the plan for the next outage.

Quick Recovery from an Outage

When a tube failure occurs, personnel must quickly identify the material and/ or stock number, as well as the weld procedure to be used. With the Aware HRSG integrity management software, this information is available from any computer on the intranet with just a few mouse clicks. In most cases, all factors can be identified in less than a minute. While accessing that information, personnel can also see the previous inspection findings, UT readings and other tube failures for the relevant component. This past information may be required to determine what type of repair should be done to avoid another forced outage in the future.

While reviewing the information, personnel can document the current tube failure and enter whatever information is known at the time. If required, a weld traveler can be generated with just a few mouse clicks. When the unit returns to normal operation, the rest of the information can be entered and, if an R-1 form is required, can be printed directly from the system.

Having quick and easy access to the right data at the right time allows plant personnel to perform their jobs more efficiently and return the unit to full operation in shorter time. The Aware HRSG integrity software impacts the bottom line by enabling a faster recovery, thus reducing the duration of forced outages.

Sharing Knowledge

Aware provides a central knowledge database for all users, whether they are at Corporate or a plant; whether they are a VP or a welder. Aware heat recovery steam generator integrity management software can be used to locate something as simple and important as material changes, or to trend something as complicated and significant as statistics on the entire fleet. Aware can also be used to save procedures, guidelines and best-practice documents, enabling swift and easy access to all users. In summary, Aware integrity software provides an easily accessed knowledge bank that is useful for all personnel responsible for keeping the plant’s HRSG’s healthy and reliable.