SUN - UL 60730-2-2, Standard for Safety for Automatic Electrical Controls

Effective March 27, 2017

Effective Date (see Processing Schedule below): March 27, 2017

Impact Statement: A review of all Listing Reports is necessary to determine which products comply with new/revised requirements and which products will require re-evaluation. NOTE: Effective immediately, this revised standard will be exclusively used for evaluation of new products unless the Applicant requests in writing that current requirements be used along with their understanding that their listings will be withdrawn on Effective Date of March 27, 2017 unless the product is found to comply with new/revised requirements.

Overview of Changes: These revisions to UL 60730-2-2 are being issued to revise the endurance test and add requirements covering deviation and drift to provide a performance/reliability bench mark for thermal motor protectors when tested to the manufacturer’s declared electrical and thermal rating.. Specific details of new/revised requirements are found in table below.

Processing Schedule: So that production of products bearing Listing Marks will not be interrupted, the following schedule of approximate dates has been established to ensure Listing Reports are found compliant by Effective Date:

- July 27, 2017 = 8 Month Report Review – Intertek will review all Reports. Update if compliance is verified or issue Findings Letter/Quote for any re-evaluations needed

- September 27, 2017 = 6 Month Quote Cut-off – Quotes returned for necessary re-evaluations

- February 27, 2017 = 30 Day Warning – Client advised of all non-compliant Reports to be Suspended

- March 27, 2017 = Effective Date – ATM Suspended for all non-compliant Reports

Fees: An initial review of Listing Report (s) will be covered by a direct billing project and will be invoiced at not more than $1000 per report.

Client Action Required:

Information – To assist our Intertek Engineer with review of your Certification Reports, please submit technical information in response to the new/revised paragraphs noted in the attached or explain why these new/revised requirements not apply to your product (s).

Current Listings Not Active? – Please immediately identify any current Listing Reports or products that are no longer active and should be removed from our records. We will do this at no charge as long as Intertek is notified in writing prior to the review of your reports.

| Clause | Verdict | Comment |

|---|---|---|

| 1.1DV DE | adding the following note after the third paragraph: Thermal motor protectors that are off-winding (not integrated with the motor winding) to the motor are covered under the scope of this part 2 and may be considered incorporated controls with respective to the requirements of this standard. | |

| 2.6.101DV D2 | Modification by adding the following notes: NOTE 1 Type 3 action applies to in-winding, integrated thermal motor protectors. NOTE 2 Type 2 action applies to off-winding, incorporated thermal motor protectors. | |

| 6.4.2DV D2 | Replacement of 6.4.2 with the following: 6.4.2DV.1 This clause of the Part 1 is applicable to thermal motor protectors declared to be incorporated with deviation, drift and endurance values in Table 7.2. 6.4.2.101DV D2 Addition: – Type 3 action. | |

| 6.11DV D2 | Modification of 6.11 by replacing it with the following: 6.11DV.1 This clause of the Part 1 is applicable for controls declared to be incorporated with endurance values in Table 7.2. 6.12 Not applicable. | |

| Table 7DV D2 | Modification of Table 7.2 with the following eight national differences: DV.1 Insert row 7, with the first column being “7”, the second column being “The type of load controlled7)”, the third column being “17, 6.2”, and the fourth column being “X”. DV.2 Insert row 27, with the first column being “27”, the second column being “Number of automatic cycles (A) for each AUTOMATIC ACTION)”, the third column being “6.11DV.1, 17.8”, and the fourth column being “X”.”. DV.3 Insert row 37, with the first column being “37”, the second column being “Minimum and/or maximum rates of change of ACTIVATING QUANTITY, or minimum and/or maximum cycling rates for a SENSING CONTROL4)”, the third column being “15, 17”, and the fourth column being “X”. DV.4 Insert row 39, with the first column being “39”, the second column being “Type of Action”, the third column being “6.4”, and the fourth column being “D”. DV.5 Insert row 41, with the first column being “41”, the second column being “MANUFACTURING DEVIATION and condition of test appropriate to deviation”, the third column being “15, 17.14”, and the fourth column being “X”. DV.6 Insert row 42, with the first column being “42”, the second column being “DRIFT”, the third column being “15, 16.2.4DV.1”, and the fourth column being “X”. DV.7 Notes 4 and 7 of the part 1 applies. DV.8 Replace note (101) with the following, “Thermal motor protectors are classified as Type 3.B.H controls. 7.101DV D2 Addition: 7.101DV.1 A protector shall be marked with the opening temperature; and, for an automatically reset protector, closing temperature. | |

| 11.101DV.2 | Any insulation for an integrated (in-winding) protector intended for use in a Class F or

higher insulated motor shall comply with the Protector Insulation Test, 13.101DV –

13.101DV.6, and with the traceability requirements specified in the Standard for

Polymeric Materials – Short Term Property Evaluations, UL 746A. – 13.101DV.6, and with the traceability requirements specified in the Standard for Polymeric Materials – Short Term Property Evaluations, UL 746A. | |

| 11.101DV.3 | Polymeric materials used in incorporated (off-winding) protectors, shall be rated for the maximum use temperature under normal operating condition of the motor. | |

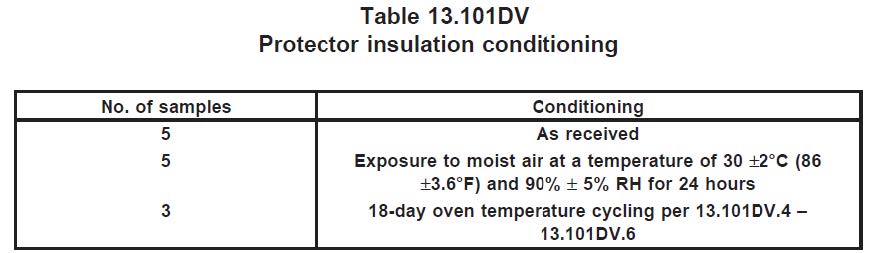

| 13.101DV D2 | Addition of protector insulation test: Eighteen samples of the tubular style insulation are to be conditioned in accordance with Table 13.101DV. Three samples are to be installed either on protectors or on metal mandrels representative of the size and shape of the protector to be insulated and submitted to the 18-day test described in Table 13.101DV. Fifteen samples are to be 4 inches (102 mm) diameter or square in the minimum thickness used or is to be of a size representative of the end-use protector and subjected to the other tests in Table 13.101DV. | |

| Table 13.101DV |  | |

| 13.101DV.2 | Following the conditioning, each sample is to be subjected to a dielectric voltage within a test chamber. For the fifteen 4 inch samples, the electrodes of the dielectric equipment shall be placed on opposite sides and in the center of the sample. For the 3 samples on the mandrel or protector body, one electrode shall be connected to the mandrel or protector body and the other should be on the opposite side of the insulation sleeve in the center of the sleeve. The voltage is to be applied at a uniform rate of 500 volts per second until breakdown occurs. When physical evidence of dielectric breakdown is not apparent, the voltage is to be reapplied until a more positive indication is produced. | |

| 15DV.1 | 15DV D2 Modification of Section 15: 15DV.1 The requirements in Section 15 are applicable to thermal motor protectors that are declared to be incorporated with deviation and drift values in Table 7.2. 15DV.2 The deviation shall not exceed ± 5K of the manufacturers declared value. 15DV.3 The drift shall not exceed ± 5K of the manufacturers declared value. | |

| 16.2.4DV 16.2.4DV.1 | D2 Modification of 16.2.4: This clause of the Part 1 is applicable. | |

| 17DV | D2 Modification of Clause 17: 17DV.1 This clause of Part 1 is applicable to thermal motor protectors only when declared in Table 7.2. All sub-clauses of the Part 1 are applicable except as follows: 17.1.3.1DV D2 Addition of the following dashed sentence: - a test of AUTOMATIC ACTION at accelerated rate specified in 17.8.4DV.1 only applies. | |

| 17.8.4DV D2 | D2 Add the following: 17.8.4DV.1 The number of automatic cycles shall be a minimum of 2000 cycles or as declared in table 7.2. The cycling rate (on-off time), locked rotor or overload current and power factor shall be declared. A synthetic or artificial load may be used to simulate the test parameters for this test. | |

| 17.14DV | D2 Add the following: 17.14DV.1 The requirement in the second dash of 17.14 applies to off-winding protectors. The fourth dash applies to protectors that have deviation, drift and endurance values declared in Table 7.2. The fifth dash of 17.14 is not applicable. | |

CUSTOMERS PLEASE NOTE: This Table and column "Verdict" can be used in determining how your current or future production is or will be in compliance with new/revised requirements.